Soundalloy MPM

constrained layer metal composite

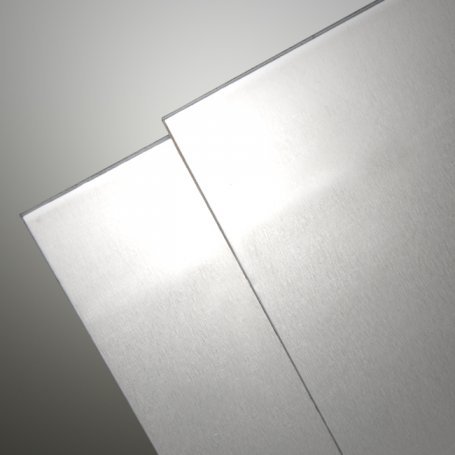

Soundalloy® MPM is a damped aluminium composite comprising two layers of aluminium laminated together using a layer of a viscoelastic polymer to form the laminate.

Using the “constrained layer” principle, the function of the viscoelastic interlayer is to damp disturbing structure borne sound.

Soundalloy MPM is free from resonance and coincidence phenomena which often detract from the performance of other acoustic insulation materials.

Using aluminium sheet allows the laminate to be used as a structural material in equipment construction.

Soundalloy MPM can be used to fabricate acoustic doors, laundry and garbage chutes, ducts, enclosures, extraction hoods, and automotive components such as valve covers & oil sumps.

Because of the aluminium base material, Soundalloy MPM can be used in severe environments which other materials cannot withstand.

Other metals such as stainless steel and EG steel can be substituted for aluminium.

Note: Powder-coated panels should not be bent. Bending should be completed on plain panels and painted on site. We recommend conducting trials on small samples pieces first.

Technical data

Soundalloy™MPM is a damped aluminium composite comprising two layers of aluminium laminated together using a layer of a viscoelastic polymer to form the laminate.

Please refer to the Technical Data Sheet (TDS) for more information.

Applications

- Engine rooms for high speed craft / vessels

- Machinery and equipment enclosures

- Compressor and generator set enclosures

- Acoustic hoods and chutes

- Conveyor systems

- Crushers / Granulators

- Coin counters

- Air conditioner casings

- Automotive sumps and panels

- Acoustic wall panels

- Acoustic doors

Features

- Maximum damping for minimum thickness

- Complies to IMO FTP 2010 – low spread of flame

- Can be used as part of the “main structure”

- Cut, form and join just like plain aluminium

- Insulates against air-borne sound, impact and vibration

- Able to be painted & powder coated – best results from the manufacturer for powder coating

- Effective “in-structure damping”

- No need for external damping materials

- Reduces or eliminates need for use of external isolators

- Lightweight damped structures

- Broad temperature range (-40°C to 110°C)

- Able to fabricate using conventional machine shop tools

- Able to be die formed into complex shapes

- Various configurations of metal thicknesses available from 1 mm – 6 mm